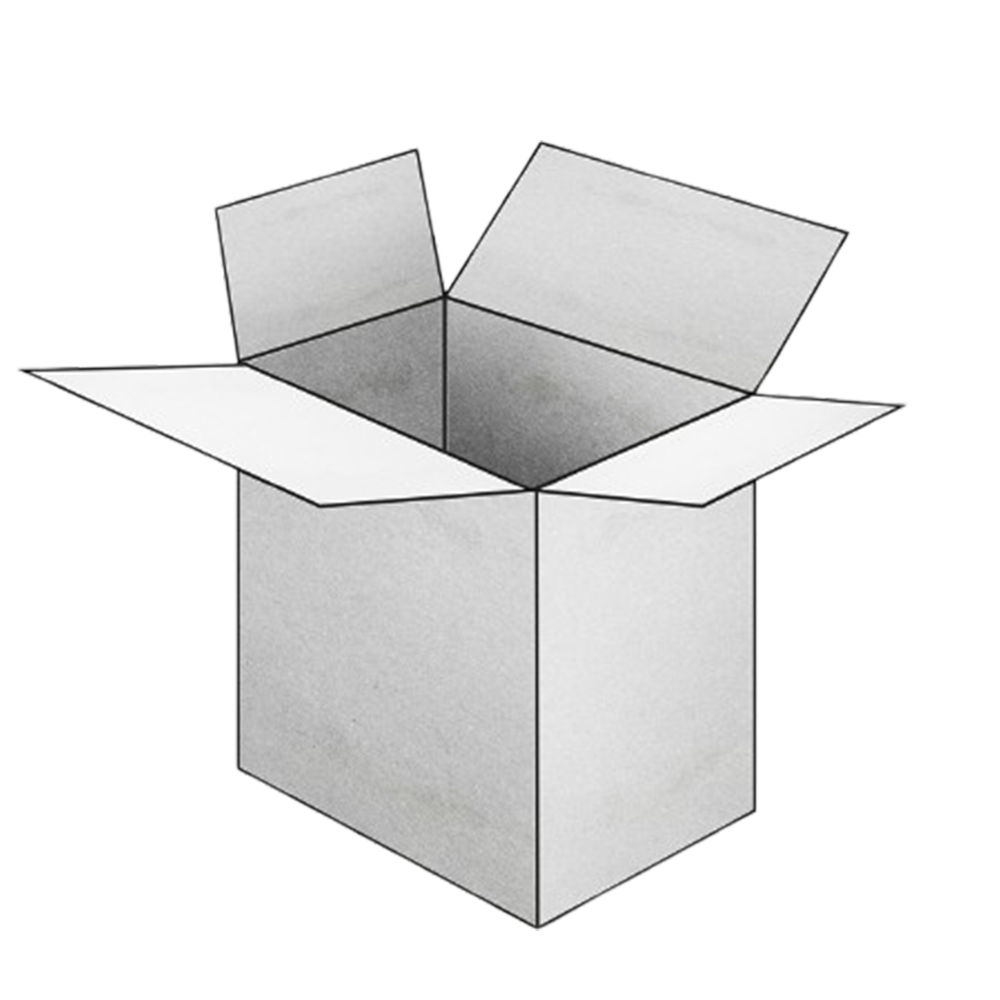

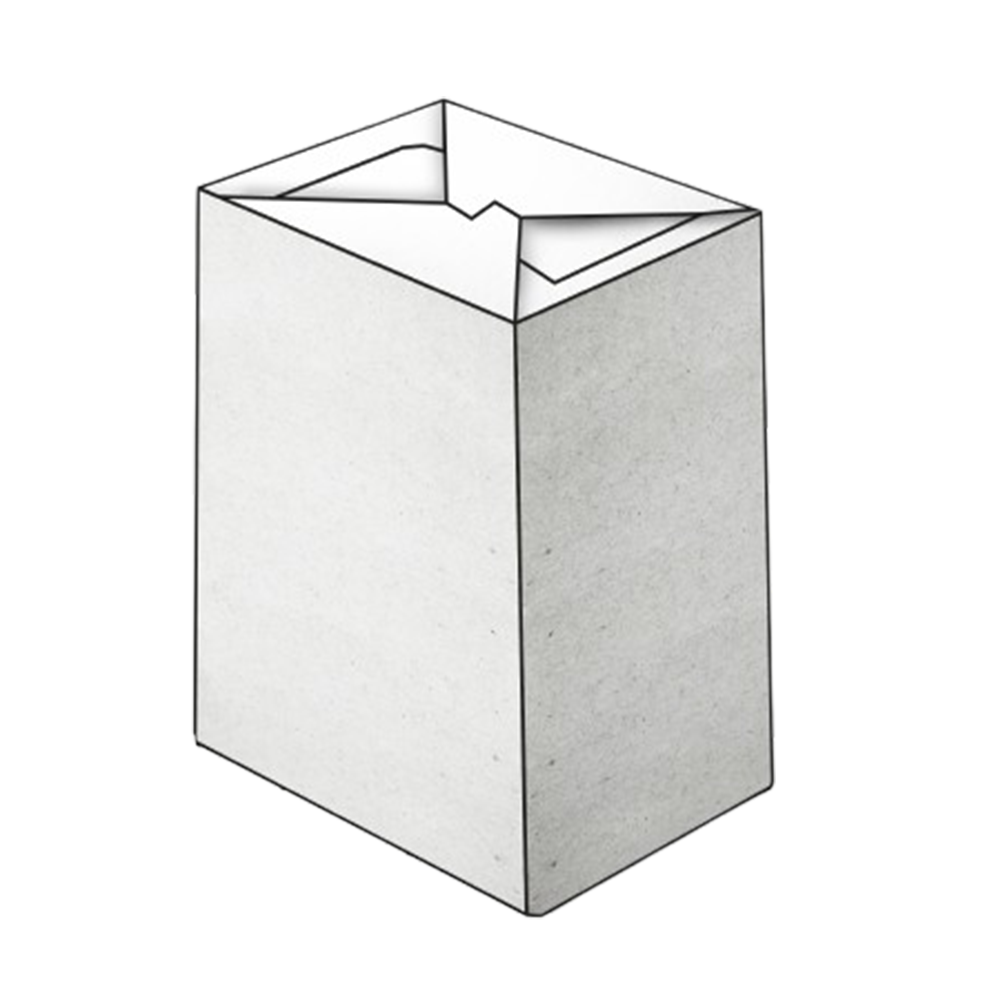

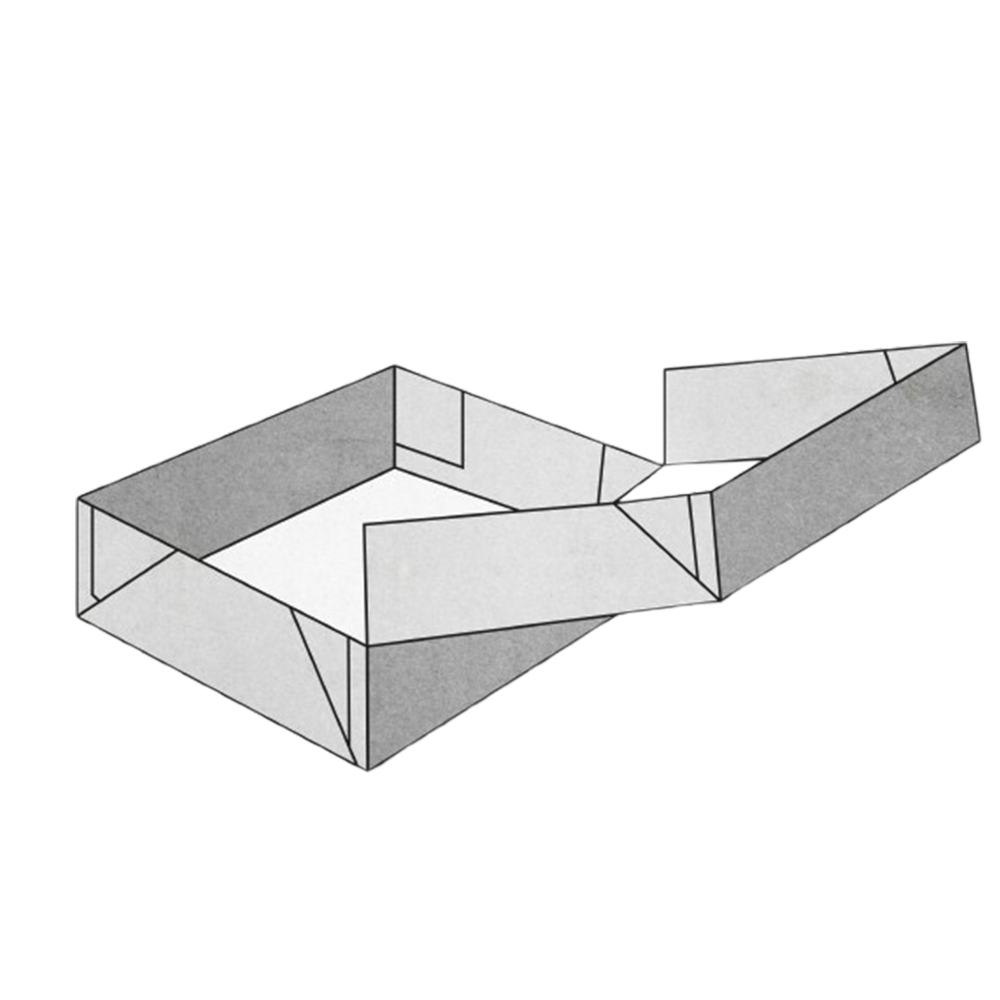

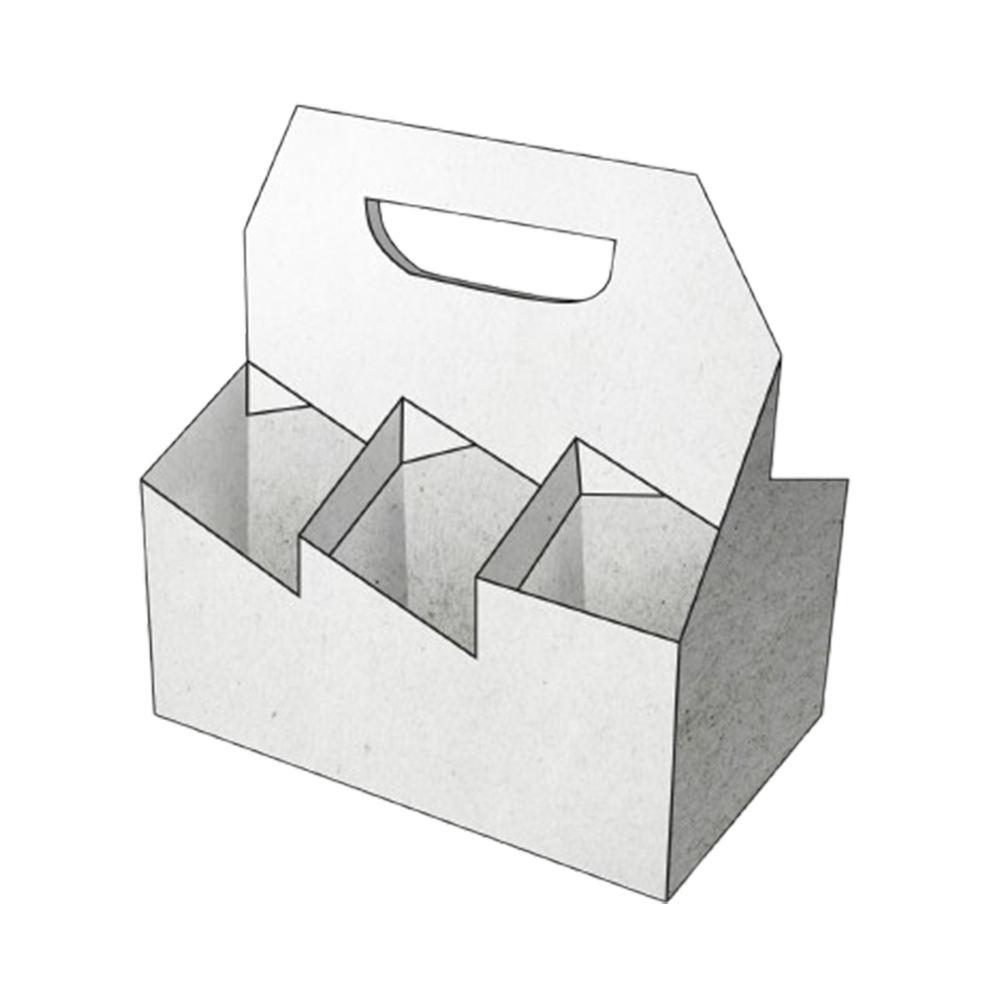

Folding carton applications

From the simple folding box to the complex six-pack

You can rely on it

Folding cartons are getting more complex all the time and no wonder, considering they have to support high-quality product presentation, protect what’s inside, serve as carriers and be as sustainable as possible. These multiple functions put growing demands on gluing and quality assurance systems. With its modular components, Baumer hhs offers a sophisticated and powerful system that meets even the highest of these technical demands: It is the industry benchmark.